SERVICES

From concept to completion…

Complete Acoustic System Integration

Luhe Silencer can provide bespoke intake- to exhaust- solutions, to your specific requirements.

Adding value to your supply chain and in turn, help reduce your lead times and costs.

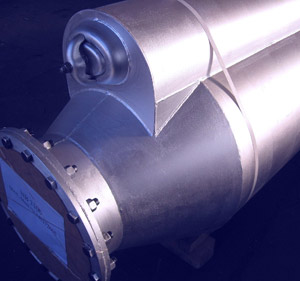

Our exhaust silencers provide the best performance for all engine applications. We offer silencers in a variety of styles and configurations, including spark-arresting and special designed silencers for gas engine applications.

Silencers

for all streaming media

- Silencers for Diesel Gas- and Dual Fuel engines

- Spark Arrestors for internal combustion engines

- Spark Arrestors and Soot Traps for boiler

- Exhaust-gas switch over valves Fire damper

- Intake air silencer

- Ventilation silencer

- Temperature-resistant All-Metal spring-tensioned Isolators for elastic support of exhaust systems

- Expansion Joints

- Accessories

Spark Arrestors

Single or Integrated

- Spark Arrestor for internal combustion engines

- Spark Arrestor and Soot Traps for boiler

Spark arrestors suitable for a variety of applications. The series can be used independently or in conjunction with silencers to form an optimal solution.

Exhaust Systems

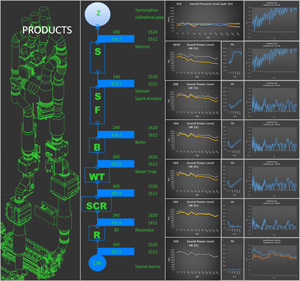

Acoustic System Design

Acoustic vibration analysis

Determination of spectral transmission- and the spectral insertion loss of specific exhaust systems.

Especially at low frequencies, the acoustic efficiency of a specific silencer design does not only depend on the silencer itself. Rather, it is strongly influenced by the position of the silencer within a system of specific geometry and the interaction with other components. Therefore, we determine the complete systems under consideration of:

- the sound generation of the sound source

- the sound propagation incl. all components inside the system

- the sound emission at the termination of the system.

Benefits

for you

- Customised silencers that meet the highest acoustic requirements

- Solutions ready for serial production

- Guaranteed mechanical and acoustic design

- Optimisation of the silencers’ pressure loss and acoustic requirements taking economic aspects into consideration

- Access to all of the experience of Luhe-Silencer

- Acoustic design of the entire system

- High engineering standards

- High quality and shortest delivery time

- Fixed prices

- Inspection and documentation of each single silencer

COMPANY

BRIEF PROFILE

With more than a half-century of experience, we engineer solutions to our customers’ unique needs and back them with unparalleled support.

Your comprehensive single-sourced solution not only meets environmental, regulatory and operational requirements, but also helps you reduce costs, improve efficiency and eliminate safety and compliance risk. We put our expertise to work solving problems for your specific needs.

Our customers are leaders in their respective markets around the world.

HISTORY

“LUHE-WERK” was founded. In the early beginning already engaged with products especially manufactured for the shipbuilding industry.

1953

A co-operation contract was signed with “CLARFELD”, a company specialized on technical insulation, about the production of silencers of all kinds.

1991

Consequentially also the development-, engineering and design departments including of all their know-how and patent rights was bought and thus the whole line of business taken over.

1997

In the context of a comprehending restructuring of “LUHE-WERK” The department Technical Noise Control including all of its activities, know-how and patent rights was outsourced. LUHE-STAHL Technical Noise Control was founded for this intended purpose. Autarkic, LUHE-STAHL all the more goal oriented could focus on the Silencer business. New international regulations as well as increasingly environmental awareness in the shipbuilding industry, the power plant industry and many other branches lead to a constantly increasing demand on technologies for noise immission control. Today the combined knowledge and the great experience in this field give L-S Technical Noise Control a leading position in the market.

2003

QUALITY

Management System

DIN EN ISO 9001 developed by TÜV Nord, established and certified.

The quality is maintained independently and is constantly updated to new laws and regulations.

Our manufacturing operation has also been verified, among others like MAN and Meyer Werft etc.

Environmental Management

In our own eco-audits the basic demands of resource techniques and procedures should be established.

Design tips for recyclable construction, use of environmentally safe materials, processing requirements for recyclable compounds.

The quality policy is firmly anchored in our corporate policy.

We want to offer our customers products and services of outstanding value. That is why we have adopted the tools for an order-Quality Management System.

We pursue the permanent objective is to produce better products at the lowest deviations.

Our staff in production and management have undertaken in the interests of our customers to apply the quality management system systematically.

We want our customers to be satisfied with us.

Our test procedure involves the following steps:

• Incoming inspection of materials

• Production control, permanent control of all manufacturing steps in production

• Final inspection of the goods by a 100% of all parts.

• Control of all critical dimensions, weld surfaces, etc.

Each of the steps is documented in the test report.

Upon request we can carry out also special tests and check routines through to our customers specifications and confirm it by the appropriate certificates. Trained personnel shall respect every step of production that defined quality requirements are strictly observed. The test procedure and test results are constantly monitored by our staff.

Your success is our motivation!

We are an independent German company. The company LUHE-STAHL Technical Noise Control GmbH was founded in 2003. We produce for our customers individual parts and assemblies for the following areas:

• Engineering

• Shipbuilding

• Plant

Our customers come from Europe, Asia, North and South America.

With our wide product range we are able to supply our customers with parts, assemblies and finished products at the lowest prices in the best quality.

REFERENCES

- All

- Cruise and Ferries

- Science and Research

- Offshore

- Merchant Ships

Cruise and Ferries

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Science and Research

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Offshore

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

Merchant Ships

Lorem ipsum dolor sit amet, consectetur adipisicing elit. Quidem, provident.

LATEST NEWS

World’s #1 trade fair for the maritime industry

Given by the overwhelming number of applications, SMM will once …

Third Ship of Quantum Class for Royal Caribbean

April 2016, MEYER WERFT delivered the 168,660-gt cruise ship Ovation …

LNG gas tanker Coral Energice delivered to Dutch shipping company Anthony Veder

The Coral Energy is already the second LNG tanker built …

Silencers from our production completed its first eastward passage

Installed on Sovcomflot’s new multifunctional icebreaking standby vessel “Fedor Ushakov“, …